BE-CU is Your Reliable CNC Machining Service Supplier in China. BE-CU is an ISO certified manufacturer in China with over 30 years of manufacturing different machining services including CNC machining services.Our team of professionals understand the importance of precision and accuracy while producing parts, so we utilize modern technologies and equipment to ensure that every product is made to the highest standard and meets our customers’ expectations. We guarantee only the highest quality materials are used in all our projects and have a stringent quality control process to make sure that each product meets the standards set by our quality assurance department. From simple prototypes to full production runs, our CNC machining services can deliver reliable results on time and within budget. We can be your perfect choice to get great designs and custom according to your designs using our CNC machining service.

- Professional CNC machining service in more than 30 years

- Popular designs and customization for your desired parts

- Complete processing machines

- Samples for the satisfaction of your order

China CNC Machining Expert

We can help you develop your final applications through our quality and effective products and satisfying fabrication. Our complete processing machines including CNC machining service are verified with experts.

Be-Cu ensures a good reputation by offering effective services and quality parts all the time. We ensure quality products before the packaging, secure and avoid moisture packaging, and fast delivery time up to 14 days.

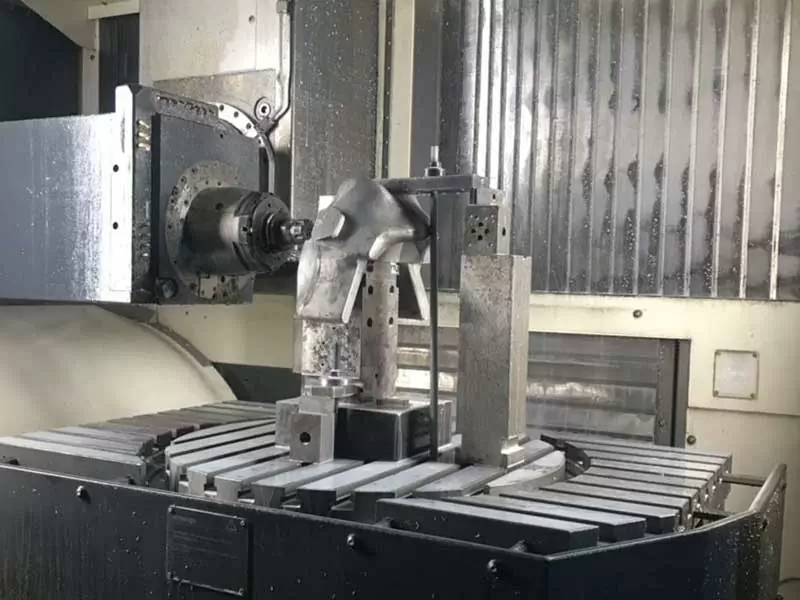

Our CNC Manufacturing Capabilities

Be-Cu Prototype Ltd provides high-quality prototyping, low and large-volume manufacturing services to support your product development needs. Our international team will work with you to make your product ideas a reality through high-tech CNC equipment and ensure your parts are shipped on time.

CNC Milling

3 Axis, 4 Axis and 5 Axis CNC Machining Service for simple and complex geometries parts.

CNC Turning

CNC turning with live tools combines lathe and milling capabilities to machine parts with cylindrical features.

Deliver your CNC Machining parts as design specifications, on time, and at a cost-effective factory price.

- Over 40 Certified Materials

- Custom Finishes

- No Minimum Order

- Fast Turnaround

If you’re looking for the right machine shop in China, we’re your source!

What Is CNC Machining?

CNC machining is a widely used manufacturing process that automates the creation of designs from metal or plastic stock using high-speed cutting tools. Standard CNC machines include 3-, 4-, and 5-axis milling machines, lathes, and routers, with variations in how parts are cut. Workpieces may be stationary while the tool moves, the tool may stay put while the workpiece is rotated and moved, or both the tool and workpiece may move in unison.

Skilled machinists program CNC machines based on CAD models to cut precise and repeatable tool paths for custom parts. CNC machining works with almost any metal or rigid plastic, making it suitable for industries from aerospace to electronics. BE-CU provides custom CNC services for over 50 materials, from commodity aluminum to advanced titanium and engineered plastics like PEEK and Ultem 2300.

Why Choose Be-Cu For Custom CNC Machining?

Be-Cu has been a trusted and expert producer of CNC machined parts. Offered one-stop solutions and complete equipment for quality production.

As your premier choice to get all your needs,Be-Cu offered long-term connections and built a close relationship to handle the next purchase easier with us.

Saving Your Cost

You will save 30-50% of the cost because of our efficient production capacity and cost control.

Quality Assurance

As an ISO 9001:2015 certificated manufacturing company, we offer SGS, RoHS, material certifications, and inspection report for our customers.

On-demand Production

Our CNC milling services will support you from 1 pcs to 10k+ pcs, no matter prototype, low volume manufacture, or mass production.

High Precision Tolerances

Offering tolerances range from +/-0.001′′ to 0.005′′, depending on client specifications. We are experts in producing custom components.

Material Selection

Choose from 50+ engineering-grade plastics and metals, including ABS, polycarbonate, nylon, PEEK, aluminum, stainless steel, platinum, and copper for diverse part applications and industries.

Fast and Reliably Delivery

Experience dependable and punctual delivery of your products from our CNC facility strategically located in Shenzhen, China, near major shipping ports for seamless transportation and peace of mind.

CNC Machining FAQs

Do you have a minimum order quantity?

NO! – No minimum quantity! Be-Cu prototype provides rapid prototypes and short to medium-run production machining services.

What type of design files does Be-Cu prototype accept for quoting?

For the 3D drawing, we would prefer STEP, IGES, or X_T format. For the 2D drawing, we would prefer PDF format there are tolerances with the dimensions if possible.

How can I pay Be-Cu prototype?

Be-Cu prototype accepts payment in two ways: 1. Bank to bank wire transfer 2. PayPal

What general tolerances can Be-Cu prototype achieve?

General CNC Machining Tolerances on metal to +/- 0.005″ (+/- 0.127 mm) following ISO 2768 unless otherwise specified. CNC Plastics and composites will be +/- 0.010”(+/- 0.254 mm).

What precision tolerances can Be-Cu prototype achieve?

CNC Precision Machining Tolerances down to ±.0002″ (0.005mm). Be-Cu prototype can manufacture and inspect to tight tolerances per your drawing specifications.

How quickly can I get my parts?

Lead times are 2 to 3 weeks for prototypes and 4 weeks for production runs. Emergency and rush services are available.