We can generally understand that the etching process is an extension of the stamping process, and it can replace the product production problems that the stamping process cannot solve. Stamping will involve mold problems, and most stamping molds are relatively expensive. Once the mold is determined, if you want to change it again, you have to open the mold again, which is easy to cause waste of molds and reduce production costs. efficiency.

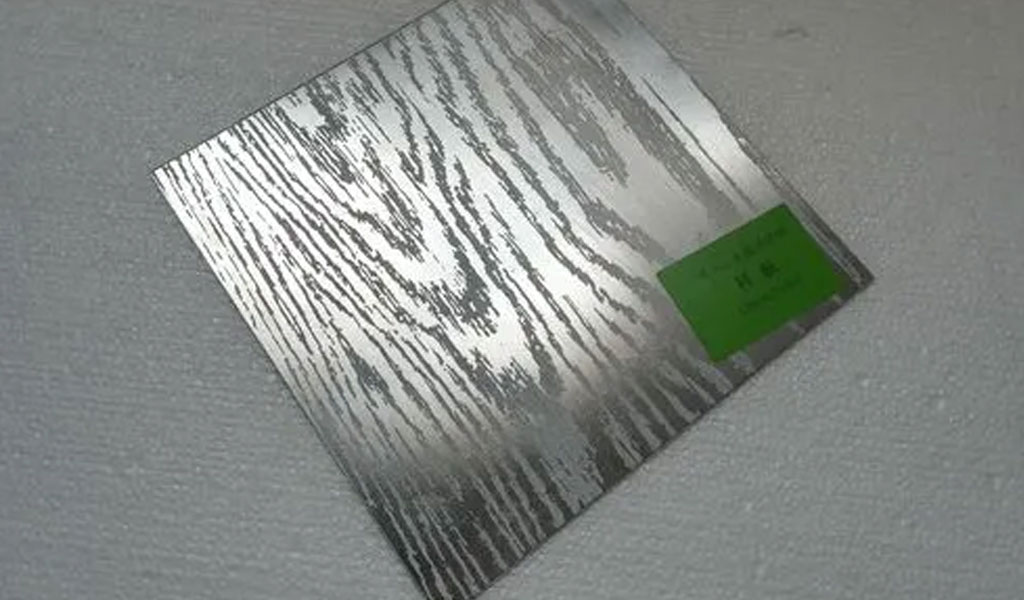

However, the machine etching process can solve the problems that the copper stamping process cannot solve, such as: the mold can be replaced and designed at any time, and the cost is low. The arbitrariness and controllability of changes have been greatly increased. It provides a wider space for designers. At the same time, it also helps the stamping process to solve the problem of stamping into the edge. However, the etching process is not a panacea. It often needs to be combined with stamping to better play their characteristics.

Generally, it is matched with stamping after etching. That is to say, the etching can be designed according to the stamping mold as the corresponding stamping positioning point of the mold. For example, forming and bending positioning holes can be processed together during etching. There are also some problems of continuous die stamping, which can also make the corresponding positioning of etching products. In this way, the problem of matching stamping after etching is well solved. The two processes complement each other! They complement each other and are widely used in the market.

Be-Cu prototype was founded in 1995 and is located in Dongguan City, southern China. At present, its production scale covers more than 50000 square meters. It has 4 factories and 3 R&D centers, 500 employees, and has obtained more than 100 invention and utility model patents.

Be-Cu prototype focuses on metal process solutions, including CNC machining, metal stamping, stainless steel etching (chemical etching) and surface treatment of OEM/ODM metal parts processing, which are widely used in toys, electronics, intelligent components, unmanned aircraft and vehicles.Be-Cu prototype mission is to become the preferred supplier for the customization of precision hardware and plastic parts in the industry.